Estos son algunos de los equipamientos de los que disponemos en el departamento para que los distintos grupos de investigación (Térmica y Fluidos, Máquinas y Vehículos, Robótica y Control, Diseño Industrial o Mechanics of Materials and Advanced Manufacturing) desarrollen sus propósitos.

CENTROS DE MECANIZADO

• Centro de mecanizado de 5 ejes UMC-500SS: husillo de 12000 rpm con cono ISO 40 y potencia 22.4 kW.

• Centro de mecanizado de 3 ejes VF-3SS con mesa giratoria HRT210 (4º eje): husillo de 12000 rpm con cono ISO 40 y potencia 22.4 kW.

• Centro de mecanizado VF-2SS: husillo de 12000 rpm con cono ISO 40 y potencia 22.4 kW.

• Centro de mecanizado DT-1: husillo de 10000 rpm con cono ISO 30 y potencia 11.2 kW.

• Centro de mecanizado Super Mini Mill 2: husillo de 10000 rpm con cono ISO 40 y potencia 11.2 kW.

TORNOS CNC

• Torno CNC ST-20 con cargador automático de piezas APL: husillo a 4000 rpm y potencia 14.9 kW.

• Torno CNC ST-15: husillo a 4000 rpm y potencia 14.9 kW.

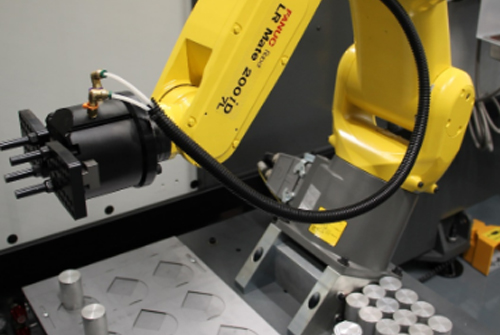

• Centro de Torneado con eje Y ST-10Y+PKG LR Mate 200iD: husillo a 6000 rpm y potencia 11.2 kW.

• Torno CNC TL-2: husillo a 1800 rpm y potencia 7.5 kW.

•Renishaw 500 S Flex: PBF-L technology with one laser. / Build volume: 250 x 250 x 350 mm. / Wide range of supported metal powders.

•Stratasys Objet60 Connex 3: Based on PolyJet photopolymer-jetting technology. / Featuring 16-micron super-thin layers. / Multi material printing capabilities. / Volume: 256 x 252 x 200 mm.

•Stratasys F170: Based on FDM technology with 254-micron layers. / Materials: ABS, ASA, PLA and elastomers. / Volume: 254 x 254 x 254 mm.

•Raise3D Pro3 Plus HS: Based on FDM technology with Dual Extruder Print. Volume: 255 × 300 × 605 mm.

•Tumaker Voladora: Nine extrusion printers. Bowden type. / One extrusion printer. Direct drive. /One pellet printer. / Build volume: 200 x 200 x 200 mm and 295 x 185 x 200 mm.

•Creality Ender 3 S1: Sixteen extrusion printers. Bowden type. / Direct extruder with filament sensor. / Build volume: 220 x 220 x 270 mm.

•Formlabs Form3: SLA technology. / Quick release system. / Build volume: 145 × 145 × 193 mm.

•Elegoo Saturn 3: DLP technology. / Build volume: 220 x 125 x 250 mm.

• 1 robot colaborativo Franka Emika de 7 ejes.

• 1 robot industrial Fanuc LR Mate 200iB de 6 ejes.

• 1 robot industrial Denso VP-6242G2M-UL de 6 ejes.

• 1 robot industrial Mitsubishi PA-10 de 7 ejes.

• 1 robot cartesiano Aula Biele de 3 ejes.

• 1 interfaz háptico Phantom Premium 1.5 de 6 GDL activos.

• 1 interfaz háptico Phantom Premium 1.0 de 3 GDL activos.

• 3 interfaces hápticos Phantom Omni de 3 GDL activos.

• 1 robot Stäubli TX60.

• 1 adaptive robot gripper Robotiq 2-finger 85.

• 8 bancadas con PLC Beckhoff EtherCAT, I/O digitales, salida analógica.

• HandySCAN 300 scanner from Creaform 3D: Laser technology capable of 200000 samples/sec. / Resolution 0.1mm and precision up to 0.04mm.

• Miraco PRO: Structured light technology. / Up to 0.02mm precisión, 0.05mm accuracy.

• SENSE 3D scanner from 3DSystems: Structured light technology. / Spatial resolution of 0.9mm at 0.5m.

• Vaquform DT2: Sheet Size: 330 mm x 250 mm. / Forming Area: 280 MM x 200 mm. / Heater Temperature: up to 280 °C.

• Mayku multiplier: Forming Area: 380mm × 380mm (250 x 180 mm with the reducing plate). / Maximum chamber pressure: 60 psi. / Heater Temperature: up to 225 °C.

• MCP KSA 100: Max. injection pressure: 410 bar. / Max. injected material: 100 grams.

• MCP 4/01: Vacuum level: 0.5 mbar. / Casting capacity: 1 l. / Max. size for the mold: 450 x 425 x 530 mm.

• Ovens for storage and curing: VGO 115S, VGO 200S.

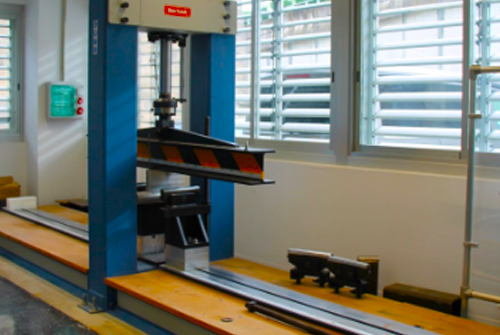

• Ibertest PEV200-W: Máquina de ensayos para flexión. / Hasta 200 kN de fuerza y 6 metros de longitud de probeta.

• Ibertest MEHP2000 5W: Máquina de ensayos para compresión de probetas de hormigón. / Hasta 2000 kN de fuerza.

• Puente grúa de hasta 1 tonelada.

• LEICA TCRM 1205: Estación total para medidas de topografía. / Motorizada. Largo alcance. / Medición de ángulos y distancia con y sin reflector.

• Proceq Profometer 5: Detector de barras de refuerzo para hormigón armado. / Determinación del recubrimiento de hormigón. / Determinación del diámetro de las barras. / Localización y orientación de las barras.

• Haver&Boecker EML 200 Pure: Tamizadora para áridos. / Tamices disponibles entre 40 mm y 63 micras.

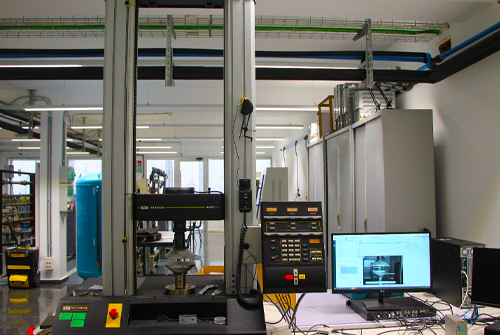

• Instron 4467: Máquina universal de ensayos. / Hasta 30 kN. Recorrido máximo de 1100 mm. / Software para registro de ensayos.

• Instron 44mini: Máquina universal de ensayos. / Hasta 500 N. Recorrido máximo de 350 mm. 7 Software para registro de ensayos.

• Instron GL50 Trav 50: Extensómetro uniaxial para la medición de deformación. / Recorrido: 50 mm. / Distancia inicial: 50 mm.

• Wolpert 7004 H1102: Máquina de ensayos Charpy. / Medida de tenacidad de materiales. / Capacidad: 4 Julios.

• Desecador de vidrio: Desecador mediante sal de sílice. / Capacidad: 10 litros.

• EPILOG HELIX24: Láser CO2 with 40 W. / Build chamber: 610 mm x 457 mm. / Max. resolution: 1200 dpi.

• Prototyping lab: it has 15 workbenches of 2000 x 1000 mm and 7 tool carts for developing prototypes.

• Máquina de medir por coordenadas TIGO SF 565: Rango de medida: X=500 mm/Y=580 mm/Z=500 mm. /

• Máquina de medir por coordenadas DEA Mistral 07.07.05: Rango de medida: X=660 mm/Y=710 mm/Z=460 mm.

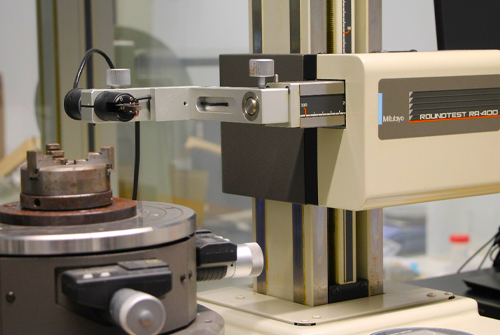

• Roundtest RA-400 de Mitutoyo: Máquina de medida de redondez.

• Surftest SJ-301 de Mitutoyo: Rugosímetro portátil.

• Form Talysurf Plus de Taylor Hobson: Perfilómetro de palpador con recorrido de 50 mm para la medición y análisis de la textura superficial.

• Microscopio estereoscópico Leica Mz 125: Cambiador de aumento 12,5:1, 0,8×–10×. / 10 posiciones acoplables en 1, 1,25, 1,6, 2, 2,5, 3,2, 4, 5, 6,4, 8.

• Microscopio SmartWLI-basic (gbs): Medición 3D de superficies sin contacto. / Principio de medición: Interferometría de luz blanca. / Campo de visión [m]: 2264x1723. / Rango de medida de altura [µm]: Up to 400.

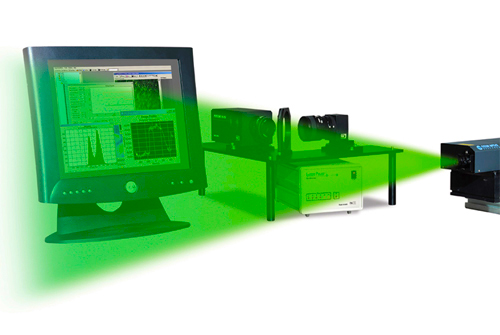

• Sistema de medición de flujos con láser TSI: Stereoscopic Particle Image Velocimetry (PIV). / Laser Induced Fluorescence (LIF). / Global Size Velocimetry (GSV).

• Anemómetros de Hilo Caliente / Hot Wire Anemometers: Hot-wire anemometry system: CTA Streamline model with two channels, an automatic calibrator and with a 3D traverse system from Dantec Dynamics.

• NVGATE OROS 35: Multianalizador en tiempo real de ruido y vibración. / 8 entradas dinámicas BNC. / 2 salidas BNC + 2 tacómetros. / Hasta 102 kS/s. / AC/DC/ICP/TEDS. / Filtros, integrador, derivador. / Software NVGate.

• GOM Aramis Ajustable 12 MP: Equipo DIC 3D. Correlación de Imagen Digital. / Medida de desplazamiento y deformación. / 8 entradas analógicas. / Extensómetro virtual para ensayos universales. / Volumen de trabajo: Hasta 770x590x590 mm.

• Equipos de extensometría: Amplificadores dinámicos de 1 canal. / Amplificadores estáticos de 4 canales. / Equipo extensométrico para metales y hormigón.

• Cámara de alta velocidad/ High speed cameras: PHOTRON FASTCAM MiniAX 200. Up to 900 Kfps; 6400 fps full frame (1024x1024). / MotionXtra HG 100-K/LE. Up to 100 Kfps.

• Cámara termográfica/ Thermal Iaging Camera: ThermaCam P25 with the research package from Flir Systems